Agriculture Machinery

Serving OEM Partners Worldwide

More Industries We Serve:

Test Results, Brochures, and Contact Information

Common Industry Bearings

Why Choose WD?

Asset Knowledge

Centuries of experience among our engineers and sales teams

Lawn and Garden: Components and Bearings

The lawn and garden industry is flush with variety. Engineering and manufacturing in an industry with so many applications brings headaches and compromises, but it doesn’t have to be that way. From lawn, grounds, and tree care to snow removal and cleaning tools, WD Bearing Group can serve nearly all positions in every lawn and garden niche.

Every application is unique to their purpose but they operate with the same general idea – harness the power of machines to create efficient and predictable motion. OEM’s who focus on crafting applications which are efficient and predictable earn the perception of “reliable”. And, of course, the power of rotation is influenced by none other more than the bearings inside the application.

Zero-Turn Lawn Mowers:

If there’s any time to make a breakthrough in the mower industry, it’s now. According to Research and Markets, the lawn mower market will reach $37 billion in the next three years.

Good lawn mower manufacturers know their customers are chasing one thing above all else: zero down-time . The purpose of a lawn mower is to make cutting the grass as easy as possible. When a machine fails to produce this function, a manageable lawn can turn to a nightmare in just a few days.

Structural Components

Zero-turn lawn mowers are the robust option for many lawn enthusiasts and agriculture professionals consisting of a frame, wheels, transmission, and an engine-powered system designed to spin blades.

A zero-turn mower’s rear-wheel transmissions are often powered by a pulley system while the spindle and blades are mounted directly onto the engine crankshaft, propelled by a hydraulic motor, or operated via a second pulley system. Bigger, faster, and stronger zero-turn lawn mowers place greater demands on the wheel bearings and spindle bearings allowing for the machine’s motion.

Bearing Components

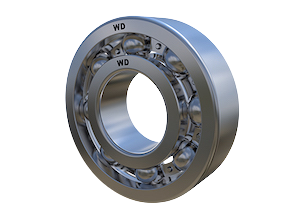

A wheel bearing sits in the center of a wheel allowing for near frictionless rotation about the axle. Too much friction between the wheel and the axle quickly wears down both parts and introduces inefficient rotation or down-time. It is common to see spindles with radial bearings typically 25mm or 30mm variants coupled with idler/pulley bearings along with speciality agriculture seals designed to keep contaminants out. The work-end of spindles typically experience both axial and radial loads and are generally fitted with deep groove ball bearings .

Mower Deck Contamination

You’d be hard pressed to find a place with more debris than the underside of an operating mower deck. Did you know the spinning blades under the mowing deck create a vacuum? Not only are the blades spinning and cutting grass, sticks, and dirt, but there is an active upward force amplifying the amount of contamination bearings have to endure.

Preventing particulates and fluids from entering into bearings is the key to maintaining a reliable machine. When free-motion is met with resistance, zero-turn mowers (and all applications) operate with reduced performance, reduced life, and suboptimal results.

Trimmers and Edgers:

Trimmers generally come in two varieties: String trimmers (also called weed eaters) and hedge trimmers. These are handheld gas or electric machines which trim grass with a rotating head and thick gauge string. Typically string trimmers are used to maintain grassy edges near surfaces like sidewalks and driveways while hedge trimmers are reserved for bushes and small trees.

Saws:

Saws are another wide category of garden tool used to remove wood. Saws utilize a gas or electric engine to rotate gear wheels that rotate chains or sets of saw teeth at regular intervals to chip and cut through wood. Common saws in the lawn and garden industry include chainsaws, pole saws, power cutters, and stump grinders.

Blowers:

Snow and leaf blowers rely on the concept of centrifugal force to eject high-powered air from their nozzles. With an electric or gasoline engine, blowers power fans to rotate at high speeds. This rotation acts on the air surrounding the blower to drive air inside and then directs it into a concentrated direction down a narrow funnel.

Blowers are generally handheld, on wheels, or worn as backpacks and come in single, two, or three stage models.

Cultivators:

Seeding, planting , harvesting , and tilling machinery are some of our very favorite applications to work with.

The Role Bearings Play

In the lawn and garden industry, rotation and contamination have no choice but to coexist. When rotation is the integral component of working lawn and garden machinery, it’s of extreme importance to find a bearing manufacturer who understands the necessity for reliability.

A reliable bearing prevents down time, break downs, and subsequent loss of revenue for your customers. Reliability comes from a few key factors:

High-Quality Steel: Maximize Bearing Life

Ultra-pure steel – that’s the ticket behind the reliable bearings from WD. Our bearings are made from 99.98% VIM-VAR steel to provide our customers with the confidence to get work done. Material quality is a major predictor for bearing life. The higher the quality, the longer the bearing lifetime. Avoiding bearing fatigue is one of the simplest ways to ensure a smooth season.

Advanced Seals: Prevent Contamination

There are fewer industries dirtier than agriculture. Even if you have high-quality steel bearings, they are only as useful as the seals protecting them from mud, dirt, grime, fluids, and the intense usage they experience.

Product Consistency: Uniform Precision

Quality creates value. Period. Consistent manufacturing, ball and roller selection, and quality control management is often overlooked when choosing bearings to create reliable machines. When a product is the same with every order, expectations can be met confidently. Consistent manufacturing processes and suppliers allow for machinery OEMs to be confident in their applications operating as intended day-after-day.

The Social Influence of Bearings in Lawn and Garden

Machines:

It is paramount to the successful operation of any OEM in the lawn and garden industry to carefully consider the bearings they choose. When generating rotation is the difference between routine maintenance and a headache, what does it say when bearings are overlooked? In many ways the decisions made with bearings influence the overall performance and lifetime of lawn and garden machinery affecting customer relationships, revenue, and perception of brand.

The bearings within lawn and garden equipment, like other components, require visual inspections and regular maintenance to increase longevity and maintain productivity of your machinery. If it’s been a while since you have evaluated the efficacy of your bearings or bearing seals, feel free to take advantage of our no-commitment-required customer application review . We’ll help you see where your opportunities for improvements are. After all, productivity drives revenue.

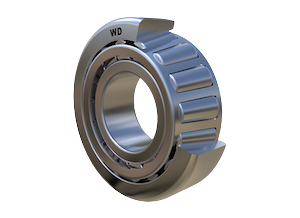

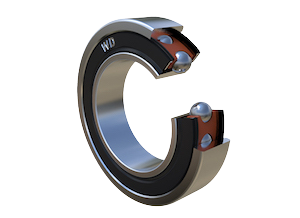

We have a

robust selection

of roller and radial bearings such as tapered

roller bearings, angular contact roller bearings, and

deep groove ball bearings.

Get the Most Out of Your Bearings

As an OEM, you need reliable bearings in the machinery you create.

Lawn and garden machinery is everywhere. And those in the agriculture industry know the difference between quality craftsmanship and poorly-made scrap. Understanding the crucial relationship between quality bearing components and agriculture machinery performance pays dividends for both you and your customers.

For more information or to order our services, contact us today.

Trusted. Experienced. Flexible.

Success Testimonials

They listened to my requirements and preferences for the design of my application and were able to offer lots of ideas to meet my needs. One year later, I am confident I have more seasons of use remaining in the bearings.

U.S. Agriculture OEM

WD listened to our requirements when we needed to refresh an aging design following a change in direction. They presented several options with a patiently designed hybrid solution.

European Gearbox OEM

The documentation at WD is clear and precise and the combination of hands on experience there is obviously of a professional nature. I would recommend WD to anyone.

Forklift OEM

Let's start something great together.

Upgrade your application. Save costs and improve performance.